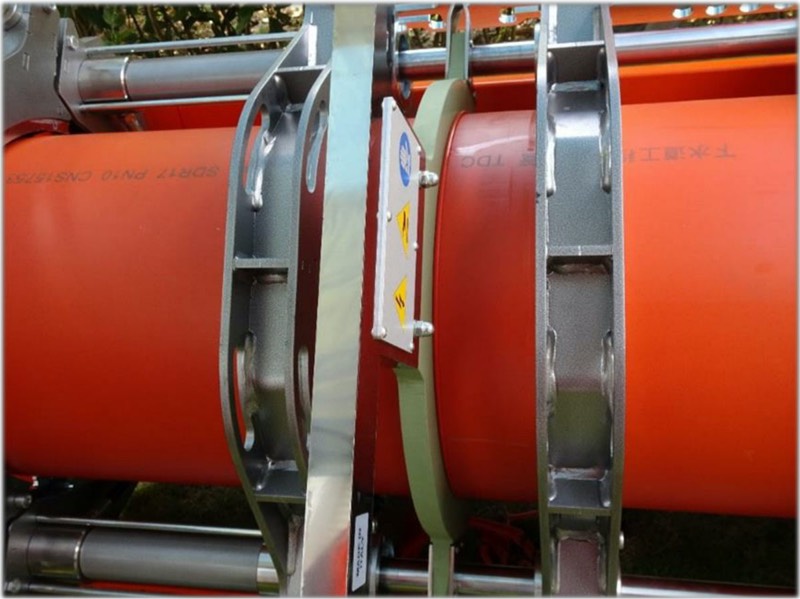

The principle of butt fusion welding is the simultaneous heating of the ends of two pipe surfaces. Then during the cooling process, pressurize two pipe together under a stable pressure. To prevent the blockages during the following cable pulling, the inner bead which is squeezed out during the cooling process must be scrapped off.

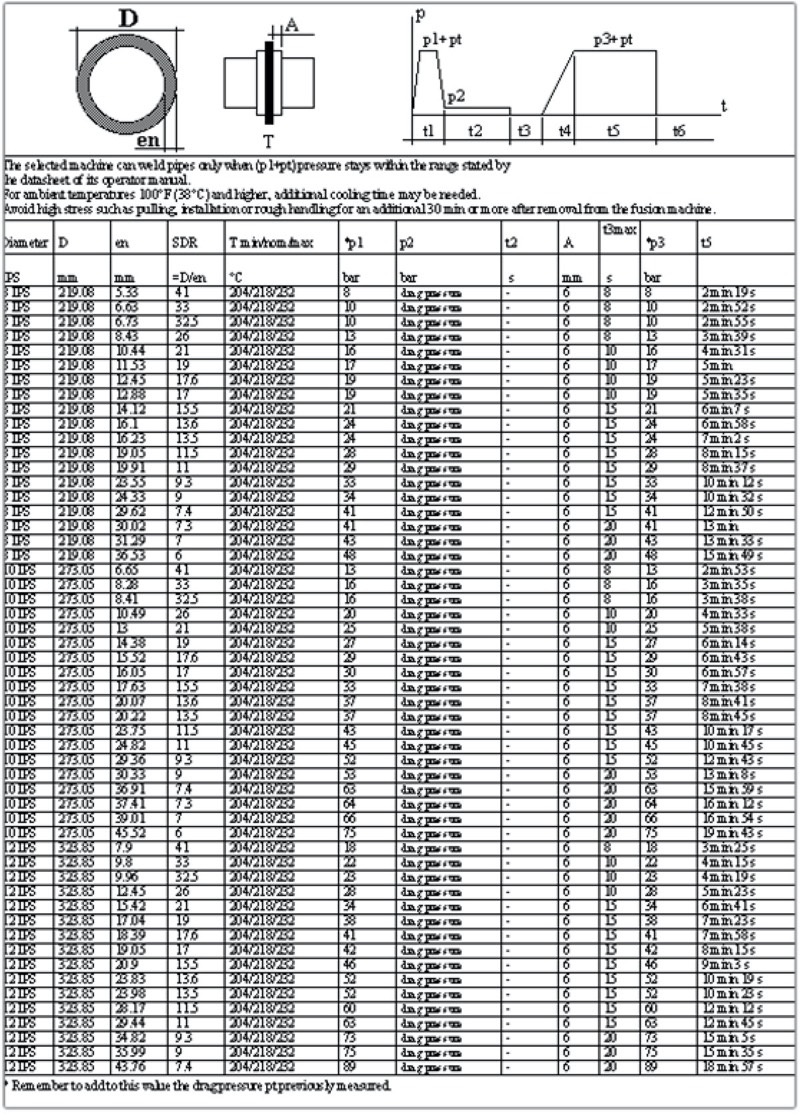

1. Set up welding parameters(pre-heating, heating, welding).

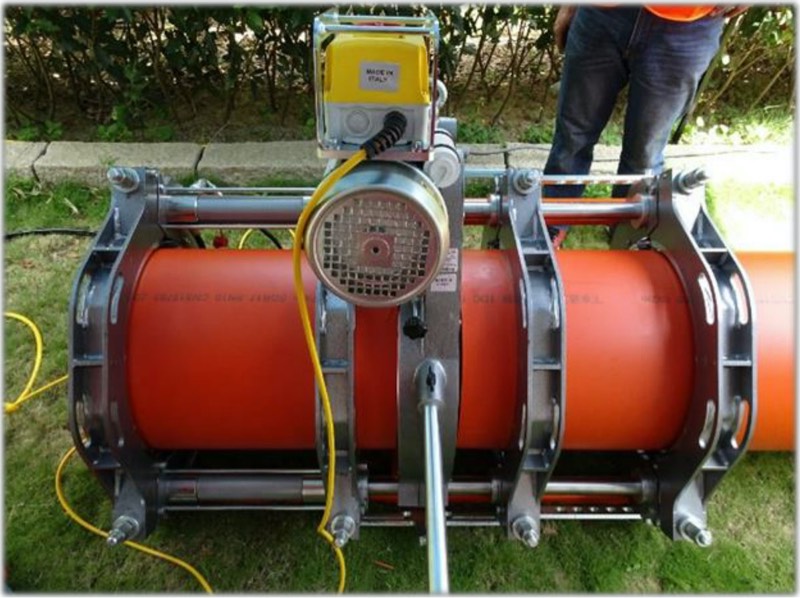

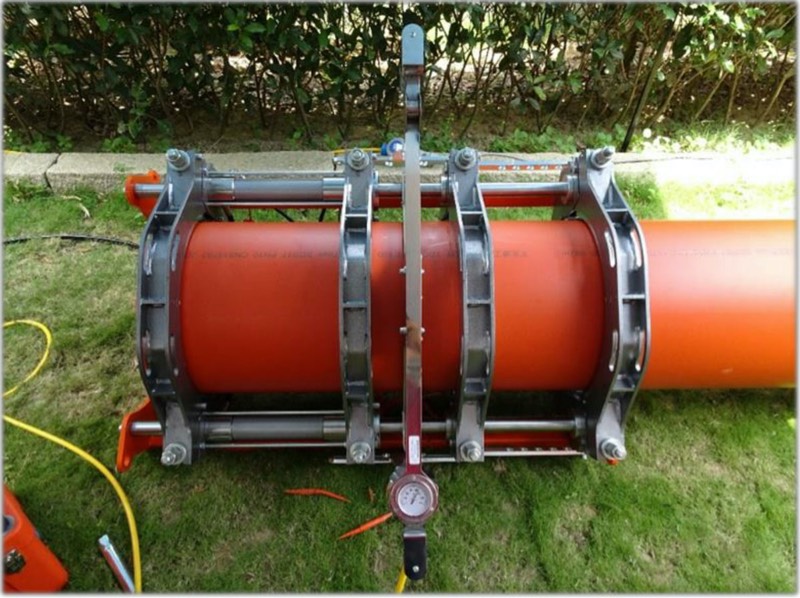

2. Insert the two pipes on both side of the clamps. Adjust the clamps to keep the pipes and the welding surfaces in parallel.

3. Place the milling cutter between the two pipes. Plane the uneven surface of both pipe ends.

4. Insert the internal debeader.

5. Inset the heating plate. Press the button, and the pipes ends will get in touch with the heating plate until set pressure.

6. Once heating is completed, the hydraulic carriage will open automatically, allowing the removal of the heating plate.

7. Press the button to start welding. Two pipes ends pressurize together for cooling in set pressure.

8. After the first third of the cooling time, insert the internal debeader and start the inner bead scraping operation. Once completed, remove the internal debeader and check if the inner bead is completely scrapped off.

9. After cooling phase, the butt fusion welding is completed. The welding report can be sent to the computer to confirm the welding quality.

If you have any queries or needs, please leave your contact data and the query you would like to consult with us,

we will have a specialist contacting you within the shortest period of time.