The principle of electrofusion welding is using electrofusion fittings with built-in heating coil to melt the fitting and pipe surfaces. The molten surfaces under pressure will join at the molecular level. Once completely cooled, the assembly co-crystallize into a single homogenous monolithic structure.

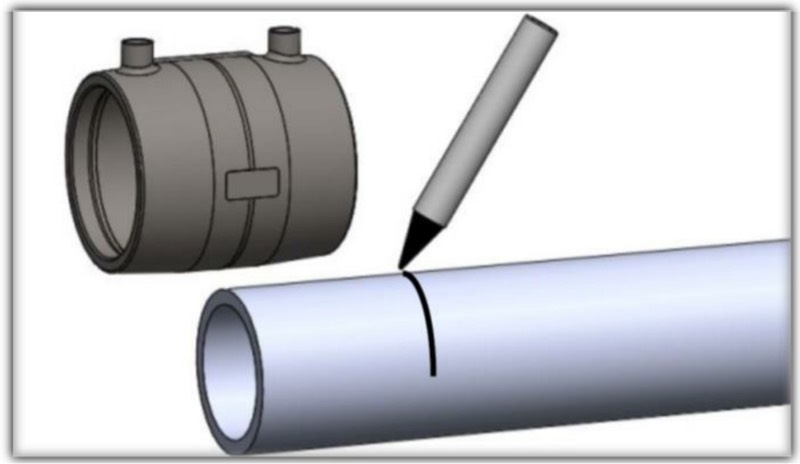

1. Mark the welding area, and scrape the oxidized pipe surface.

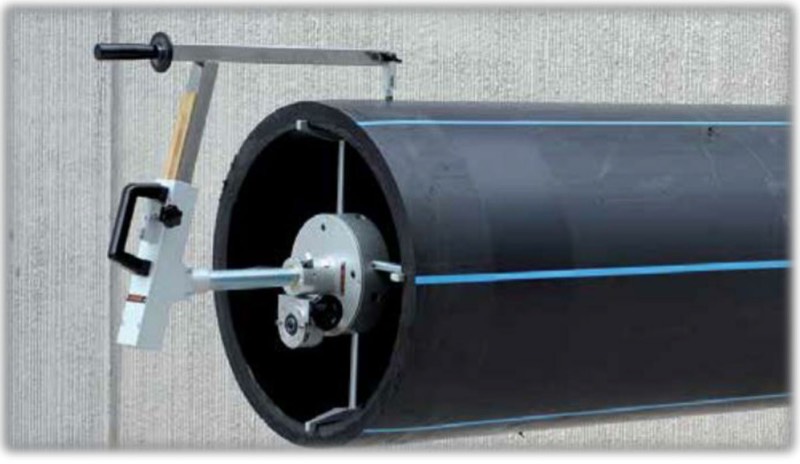

2. Clean the pipe surface as well as the inner side of the fitting.

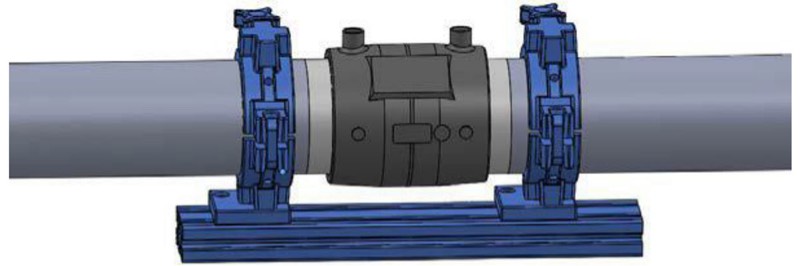

3. Insert the pipe into the fitting to the stab depth marks. Secure the pipe and fitting assembly in an alignment clamp.

4. Connect the welding machine to the fitting, scan or insert proper welding parameters into the machine, and weld the fitting. After welding is complete, do not move or disturb during the cooling time.

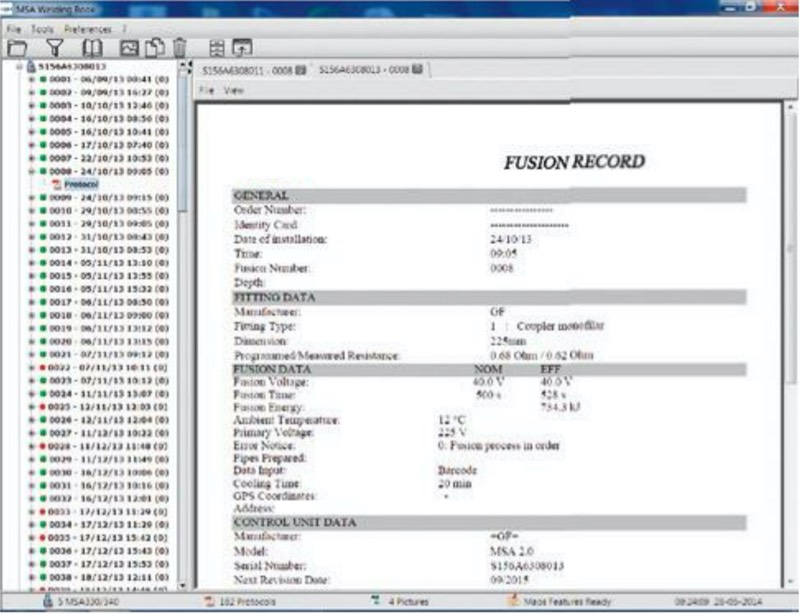

5. After cooling , the electrofusion welding is completed. The welding report can be sent to the computer to confirm the welding quality.

If you have any queries or needs, please leave your contact data and the query you would like to consult with us,

we will have a specialist contacting you within the shortest period of time.